Ini adalah entri skema yang terakhir....

TOPSIDE:

– Facilities are tailored to achieve weight and space saving

– Incorporates process and utility equipment

1 Drilling Rig

2 Injection Compressors

3 Gas Compressors

4 Gas Turbine Generators

5 Piping

6 HVAC

7 Instrumentation

8 Accommodation for operating personnel.

9 Crane for equipment handling

10 Helipad

PLATFORM PARTS

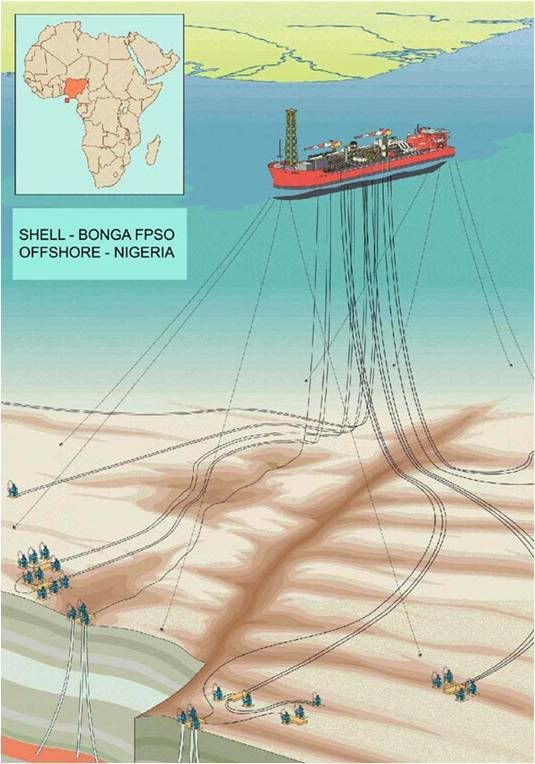

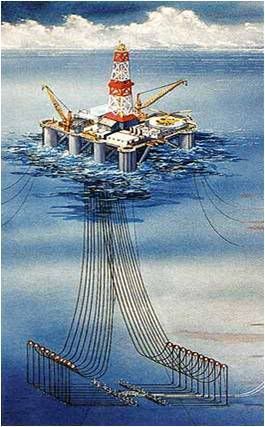

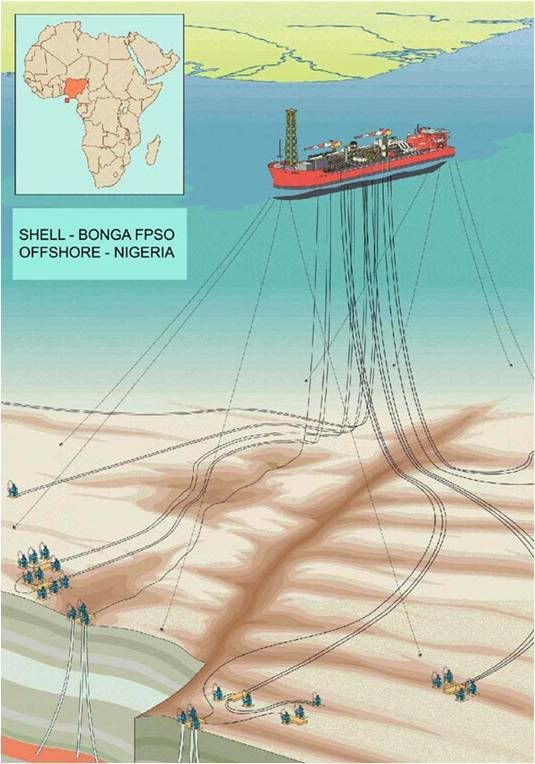

1 MOORINGS & ANCHORS:

– Used to tie platform in place

– Material

2 Steel chain

3 Steel wire rope

– Catenary shape due to heavy weight.

– Length of rope is more

4 Synthetic fiber rope

– Taut shape due to substantial less weight than steel ropes.

– Less rope length required

– Corrosion free

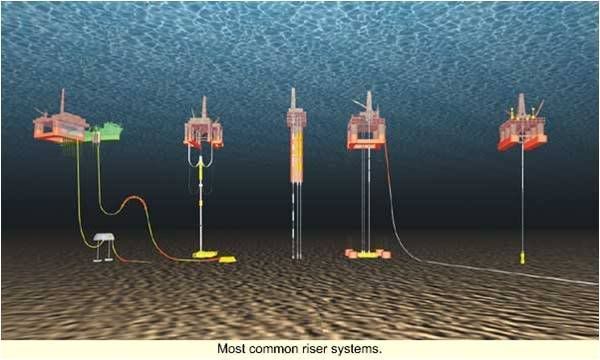

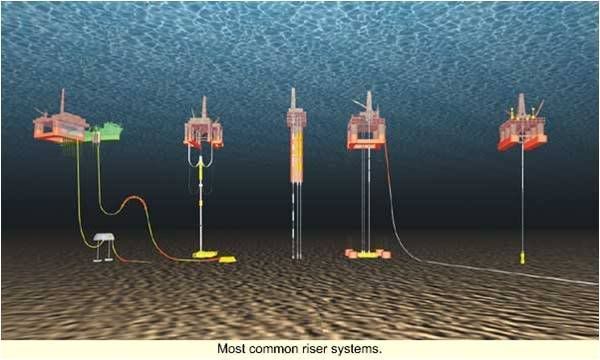

PLATFORM PARTS (RISER

– Pipes used for production, drilling, and export of Oil and Gas from Seabed.

– Riser system is a key component for offshore drilling or floating production projects.

– The cost and technical challenges of the riser system increase significantly with water depth.

– Design of riser system depends on filed layout, vessel interfaces, fluid properties and environmental condition

Semoga dengan sedikit maklumat yang diberikan didalam 3 bahagian entri berkaitan platform yang telah disiarkan memberi cukup kefahaman kepada pembaca berkaitan pelantar minyak dan bahagian-bahagiannya.

TOPSIDE:

– Facilities are tailored to achieve weight and space saving

– Incorporates process and utility equipment

1 Drilling Rig

2 Injection Compressors

3 Gas Compressors

4 Gas Turbine Generators

5 Piping

6 HVAC

7 Instrumentation

8 Accommodation for operating personnel.

9 Crane for equipment handling

10 Helipad

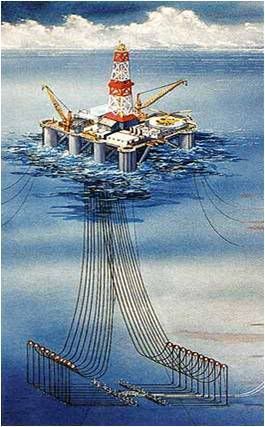

PLATFORM PARTS

1 MOORINGS & ANCHORS:

– Used to tie platform in place

– Material

2 Steel chain

3 Steel wire rope

– Catenary shape due to heavy weight.

– Length of rope is more

4 Synthetic fiber rope

– Taut shape due to substantial less weight than steel ropes.

– Less rope length required

– Corrosion free

PLATFORM PARTS (RISER

– Pipes used for production, drilling, and export of Oil and Gas from Seabed.

– Riser system is a key component for offshore drilling or floating production projects.

– The cost and technical challenges of the riser system increase significantly with water depth.

– Design of riser system depends on filed layout, vessel interfaces, fluid properties and environmental condition

Semoga dengan sedikit maklumat yang diberikan didalam 3 bahagian entri berkaitan platform yang telah disiarkan memberi cukup kefahaman kepada pembaca berkaitan pelantar minyak dan bahagian-bahagiannya.

2 comments:

terbaik bos ...

Entri selepas ni lagi terbaek dr ni kot...pasal 3 entri yg lepas ni agak skema sikit maklumlah setiap yg berunsur fakta & info ni kena skema kot.

Entri selepas ni dah tak skema dah..back to normal

Post a Comment