Kali ni aku nak cerita sikit tentang Platform,izinkan aku tulis dalam bahasa Inggeris (sebenarnya copy & Paste je)nak translate ke BM malas pulak rasanya….idea dry….

Offshore platforms are used for exploration of Oil and Gas from under Seabed and processing.The First Offshore platform was installed in 1947 off the coast of Louisiana in 6M depth of water. Today there are over 7,000 Offshore platforms around the world in water depths up to 1,850M

Platform size depends on facilities to be installed on top side eg. Oil rig, living quarters, Helipad etc.

Classification of water depths:

< 350 M- Shallow water

< 1500 M - Deep water

> 1500 M- Ultra deep water

US Mineral Management Service (MMS) classifies water depths greater than 1,300 ft as deepwater, and greater than 5,000 ft as ultra-deepwater.

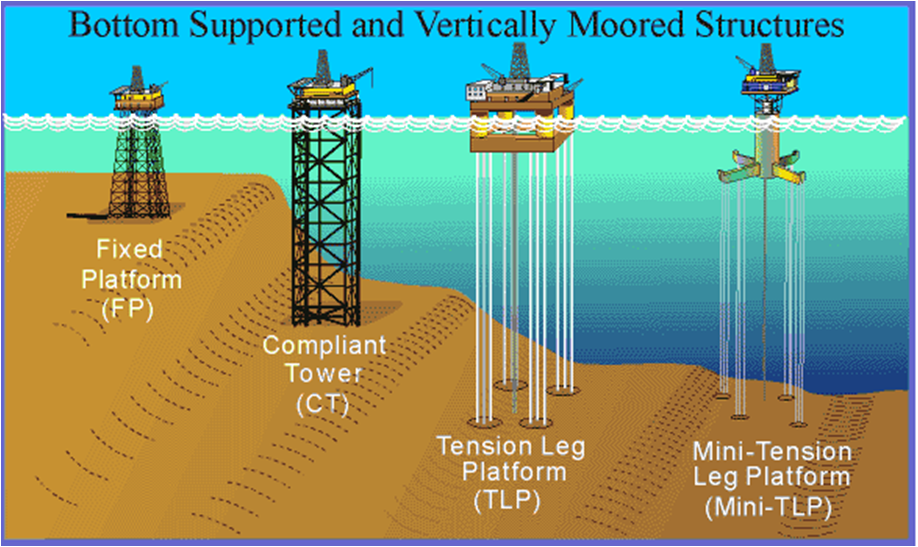

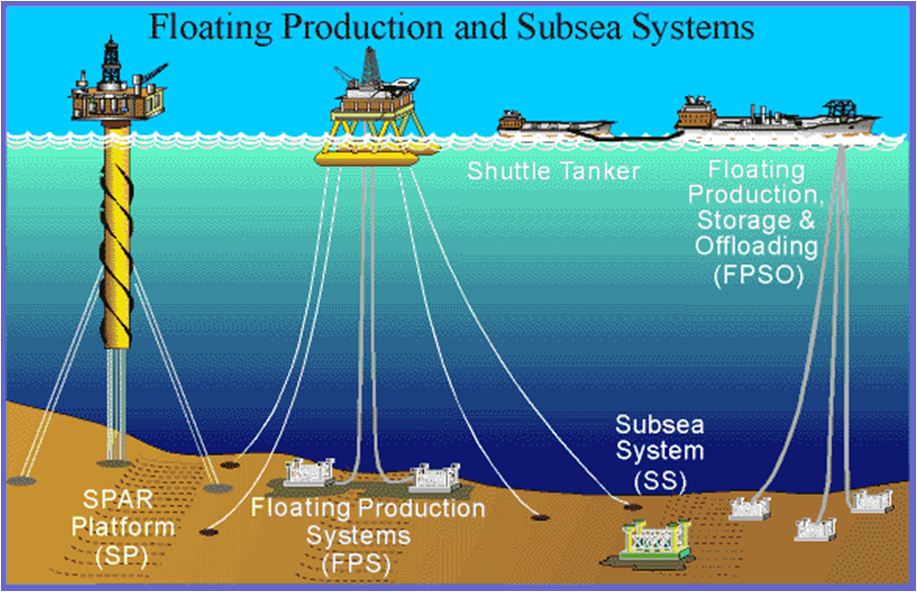

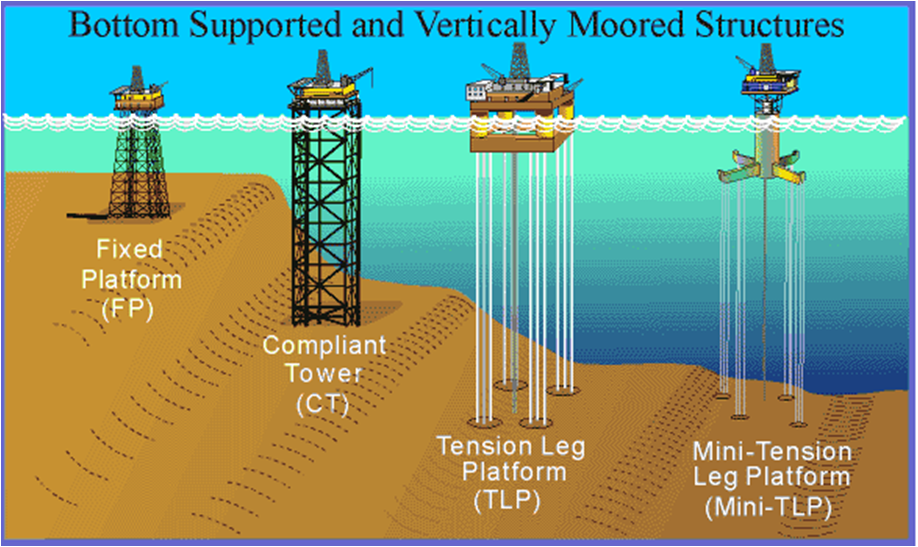

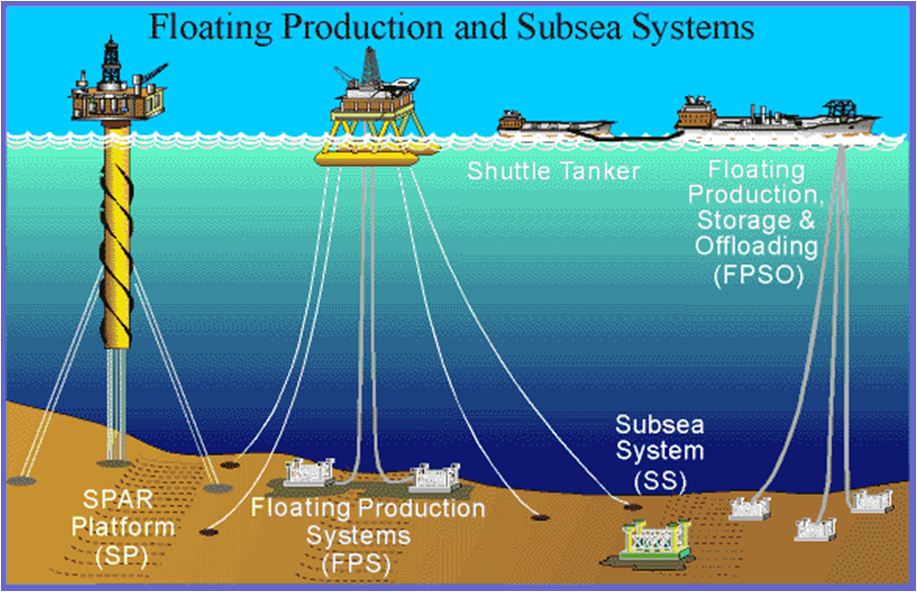

Offshore platforms can broadly categorized in two types

Fixed structures that extend to the Seabed.

- Steel Jacket

- Concrete gravity Structure

- Compliant Tower

Structures that float near the water surface- Recent development

- Tension Leg platforms

- Semi Submersible

- Spar

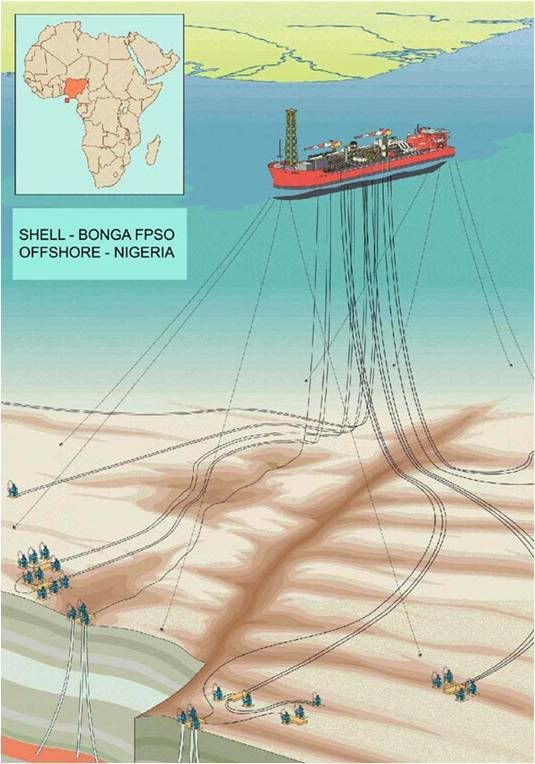

- Ship shaped vessel (FPSO)

TYPE OF PLATFORMS (FIXED)

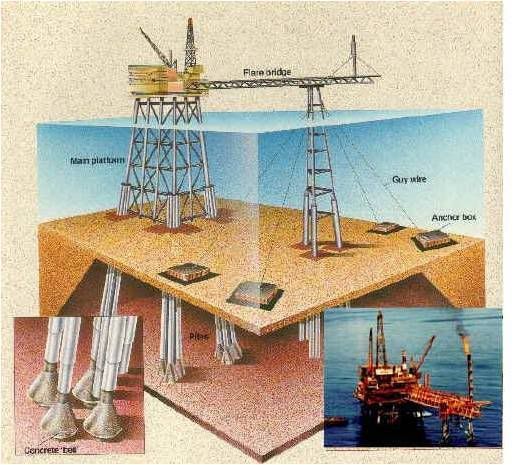

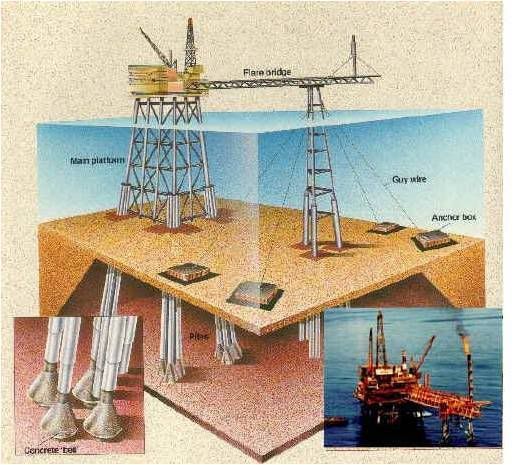

JACKETED PLATFORM (FIXED)

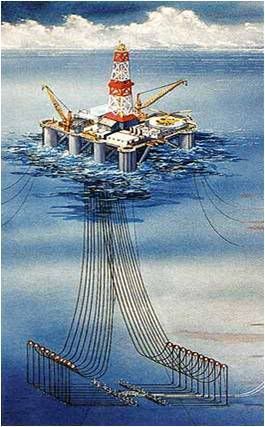

- Space framed structure with tubular members supported on piled foundations.

- Used for moderate water depths up to 400 M.

- Jackets provides protective layer around the pipes.

- Typical offshore structure will have a deck structure containing a Main Deck, a Cellar Deck, and a Helideck.

– The deck structure is supported by deck legs connected to the top of the piles. The piles extend from above the Mean Low Water through the seabed and into the soil.

– Underwater, the piles are contained inside the legs of a “jacket” structure which serves as bracing for the piles against lateral loads.

– The jacket also serves as a template for the initial driving of the piles. (The piles are driven through the inside of the legs of the jacket structure).

– Natural period (usually 2.5 second) is kept below wave period (14 to 20 seconds) to avoid amplification of wave loads.

– 95% of offshore platforms around the world are Jacket supported.

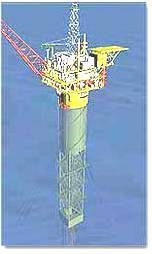

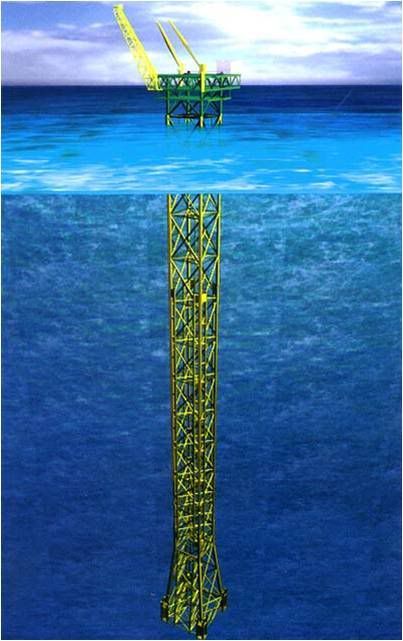

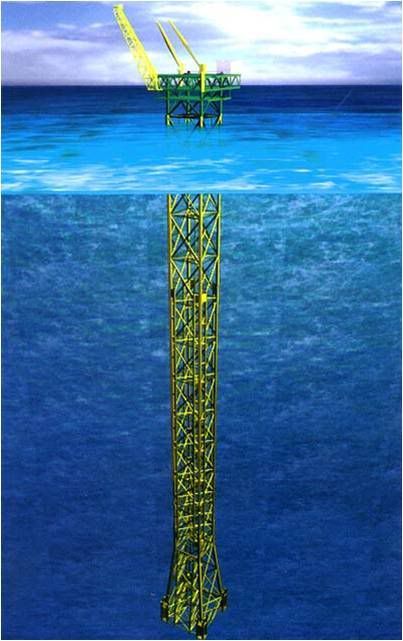

COMPLIANT TOWER(FIXED)

– Narrow, flexible framed structures supported by piled foundations.

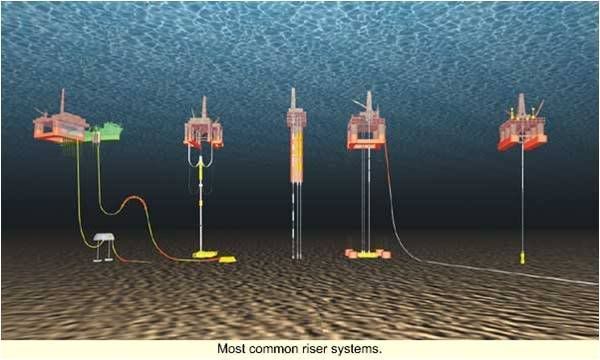

– Has no oil storage capacity. Production is through tensioned rigid risers and export by flexible or catenary steel pipe.

– Undergo large lateral deflections (up to 10 ft) under wave loading. Used for moderate water depths up to 600 M.

– Natural period (usually 30 second) is kept above wave period (14 to 20 seconds) to avoid amplification of wave loads.

TYPE OF PLATFORMS (FIXED)

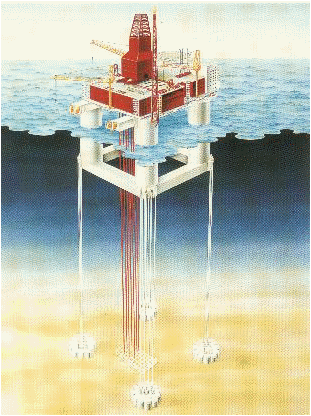

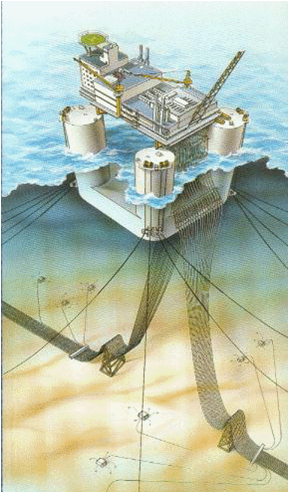

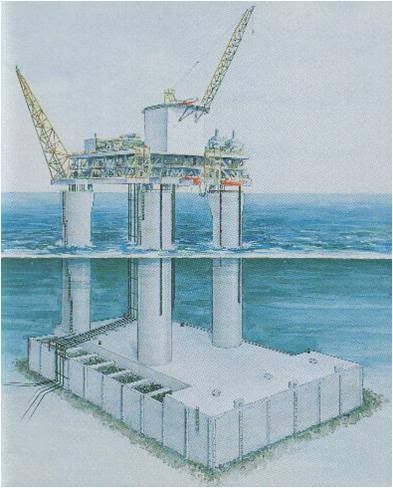

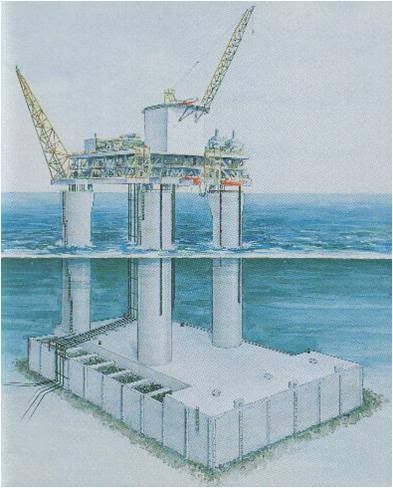

CONCRETE GRAVITY STRUCTURES:

– Fixed-bottom structures made from concrete

– Heavy and remain in place on the seabed without the need for piles

– Used for moderate water depths up to 300 M.

– Part construction is made in a dry dock adjacent to the sea. The structure is built from bottom up, like onshore structure.

– At a certain point , dock is flooded and the partially built structure floats. It is towed to deeper sheltered water where remaining construction is completed.

– After towing to field, base is filled with water to sink it on the seabed.

– Advantage- Less maintenance

To be Continue....more information about platform coming up next entry....